True cooking enthusiasts will have noticed that not all pasta is the same. Some shapes have a matte appearance and a rough surface, while others are smooth and glossy. This isn’t magic, it’s the result of extrusion, a crucial step in the pasta-making process. This is the exact moment that determines how pasta and sauce will come together.

At Valdigrano, we believe that true quality doesn’t lie in a single method, but in the ability to offer the right pasta for every culinary need.

What Is pasta extrusion?

Extrusion is the heart of dry pasta production.

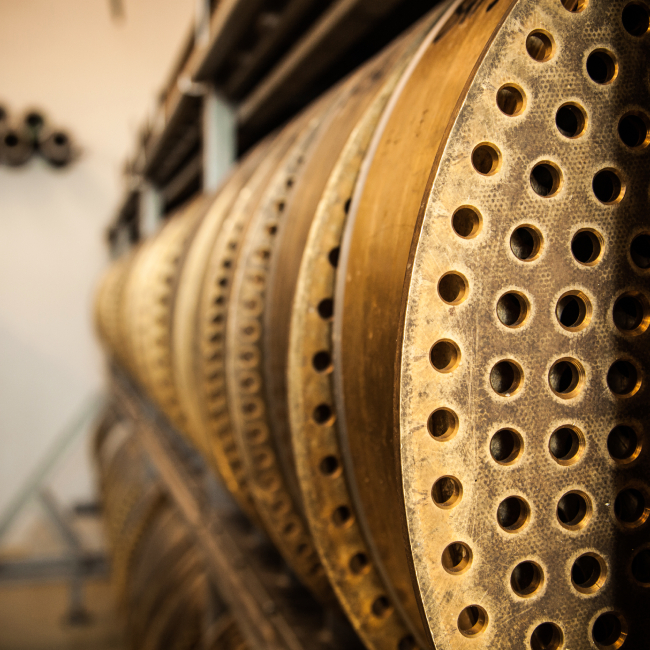

It is the process in which a dough made from semolina and water, once mixed and made homogeneous, is forced through a perforated die (called a die or matrix).

The die determines the shape of the pasta, while the material of the die defines its texture, the outer surface of the pasta. Bronze and Teflon, being very different materials, impart completely different surface characteristics, which strongly influence how pasta interacts with cooking water and, above all, with sauce.

Bronze-die extrusion: the texture that makes sauce fall in love

Bronze-die extrusion is a ritual deeply rooted in the great Italian tradition. It is the preferred method for those seeking maximum performance in the kitchen.

When the semolina-and-water dough passes through bronze dies, this softer metal creates slight friction, giving the pasta a distinctive finish:

• Rough texture: the pasta has a coarse, slightly powdery, almost porous surface.

• Maximum sauce adhesion: thanks to this porosity, the pasta excels at holding onto sauces.

• Slow, gentle drying: bronze-die pasta requires longer drying times (up to 24–48 hours for certain shapes) and low temperatures (never above 60°C). This step is essential to preserve the semolina’s organoleptic properties, natural color, and aroma, resulting in a fuller, more intense flavor.

Teflon-die extrusion: stability and perfect cooking performance

Although bronze is often celebrated, Teflon-die extrusion (using a high-resistance polymer) has its own strengths and offers indispensable advantages for specific pasta types and recipes:

• Smooth, glossy surface: Teflon’s non-porous nature allows the dough to flow quickly, producing pasta with a smoother, more compact surface and a lighter, more uniform color.

• Excellent cooking stability: one of the main benefits of Teflon-die pasta is its outstanding cooking resistance. It holds its shape perfectly and performs beautifully in longer cooking times or when vigorously tossed and finished in a pan. Ideal for those who need a pasta that won’t easily overcook.

• Ideal for delicate flavors: the smooth surface makes it the right choice when you want the sauce, perhaps a light fresh tomato sauce or a vegetable-based dressing—to coat the pasta gently without overpowering it. Teflon-die pasta is also often preferred for filled pasta, as the smooth surface helps seal the edges more effectively.

The Truth About Color

It’s often said that only matte pasta is high quality. That’s generally true—but with an important clarification.

If Teflon-die pasta appears excessively yellow and shiny, it may indicate that it was dried at very high temperatures to speed up production. This thermal shock can denature the semolina proteins and reduce its aroma.

The Perfect Match: Shape, Sauce, and Extrusion

To make choosing easier, here’s a quick guide to pairing extrusion methods with common sauces, because every sauce deserves its perfect match.

Rich, dense sauces, such as meat ragù, pair best with bronze-die pasta. Its rough surface is essential for gripping every bit of sauce. Ideal shapes include rigatoni or fusilli, whose hollow or robust forms are perfect for capturing the sauce.

Creamy or fat-based sauces, like pesto or carbonara, also shine with bronze-die pasta. The porous surface helps create the right emulsion with the sauce’s fat. Shapes with a wide surface area, such as linguine or fettuccine, are ideal.

Light, fluid sauces, such as a simple garlic-and-oil pasta, work beautifully with Teflon-die pasta, allowing the sauce to coat the strands delicately. Teflon is also the best choice when maximum resistance is required—such as for pasta salads or baked pasta dishes that need to hold up over time. Think of fusilli or farfalle: their compact structure helps prevent breakage when mixed cold.

Whether you choose the roughness of bronze or the stability of Teflon, what Valdigrano always guarantees is passion, carefully selected raw materials, and uncompromising production quality.